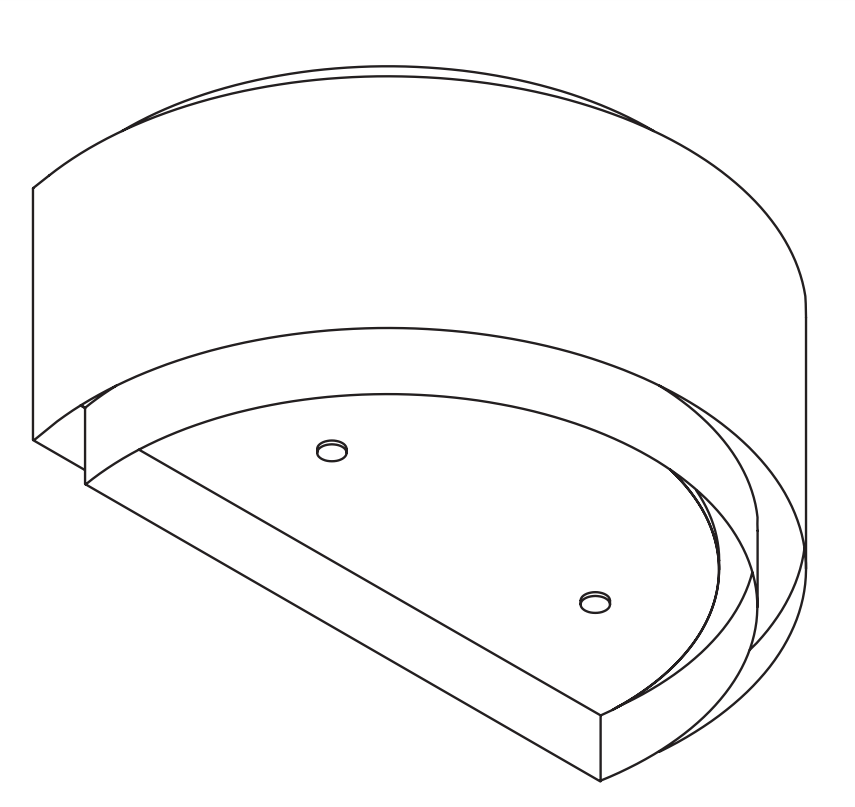

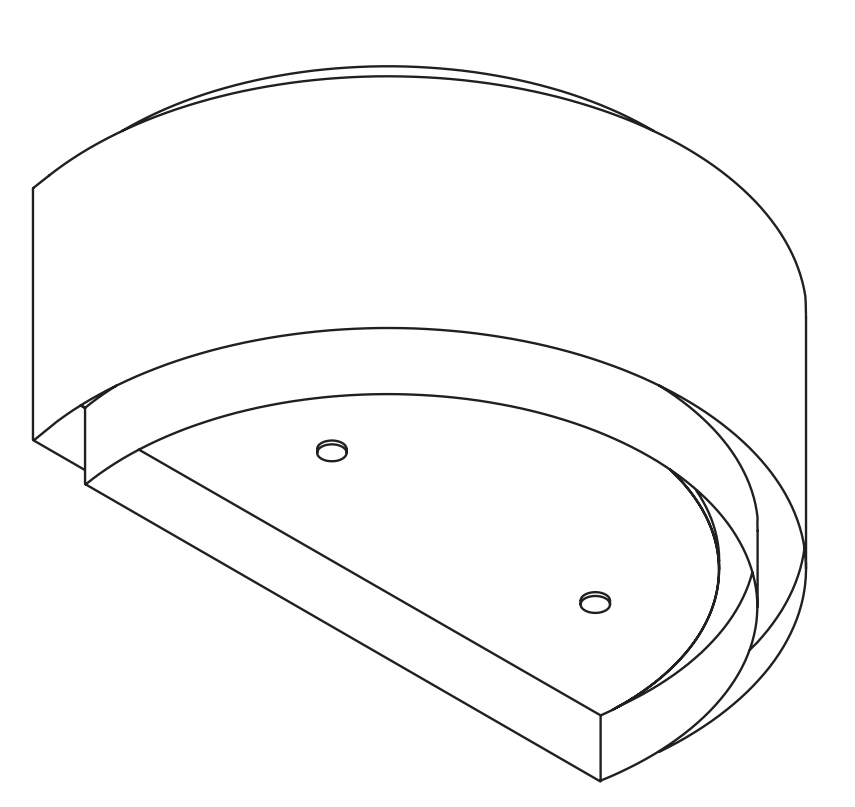

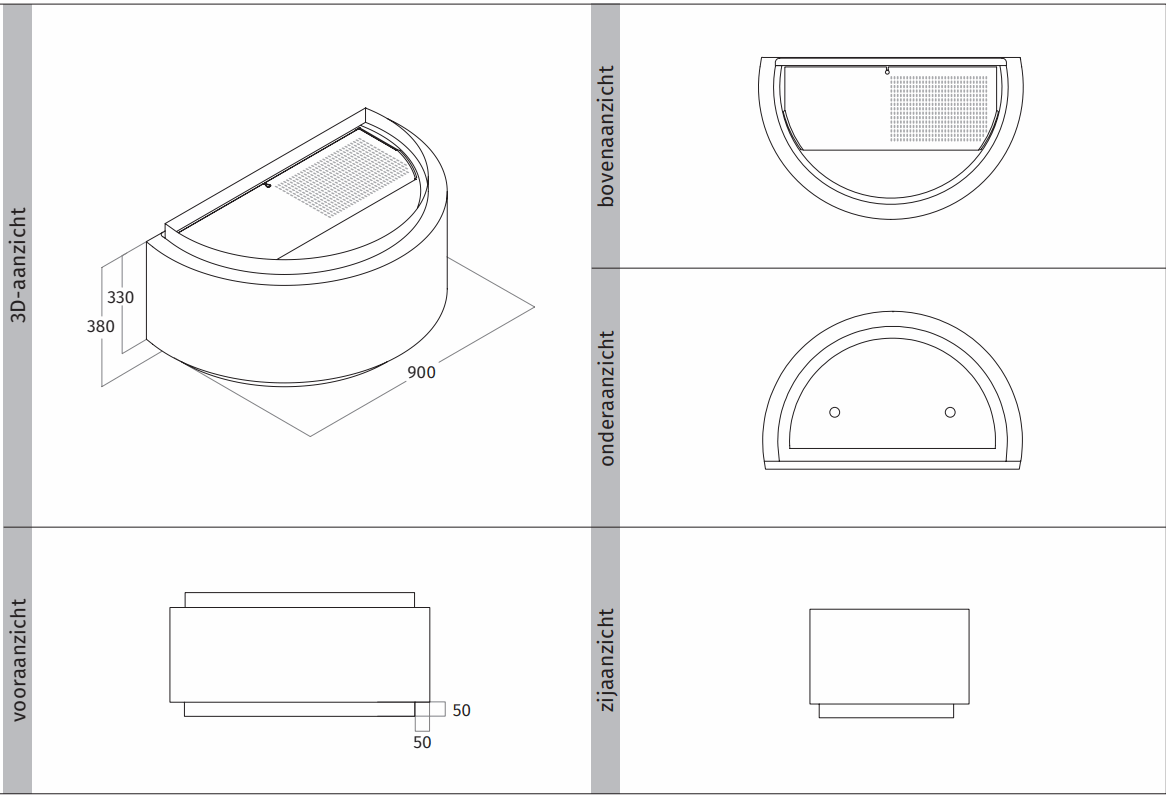

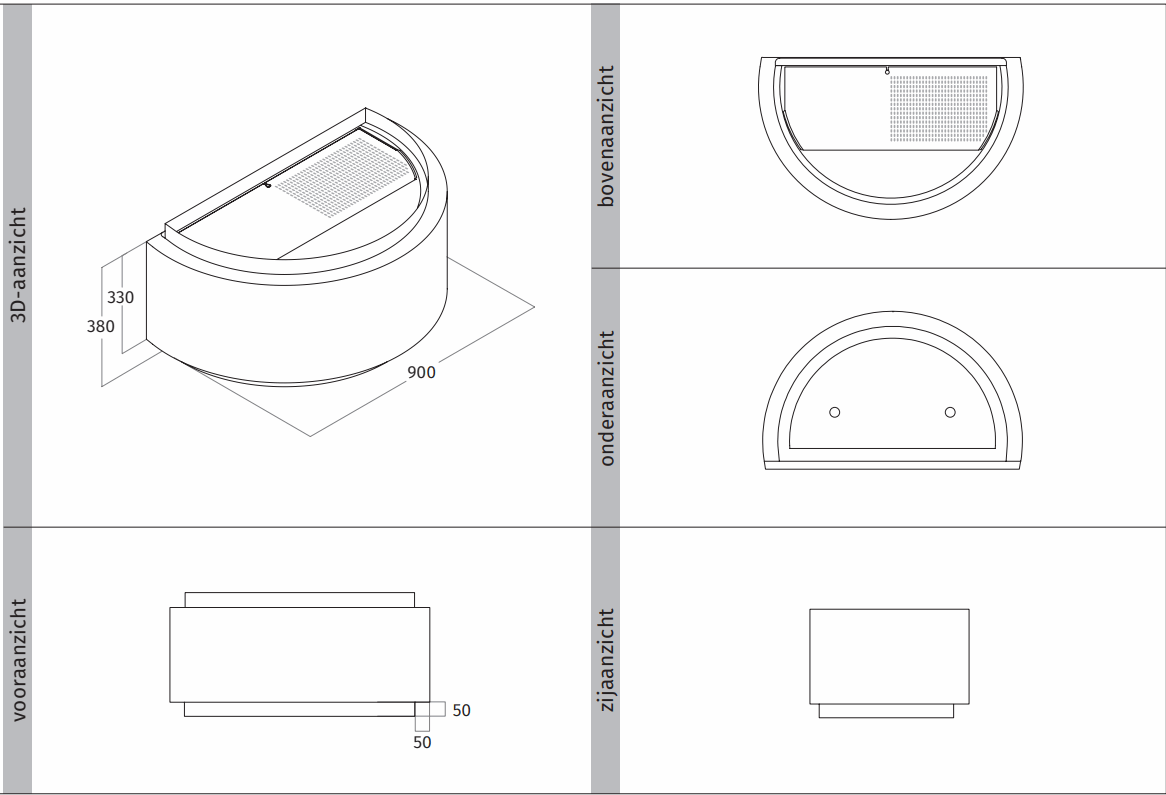

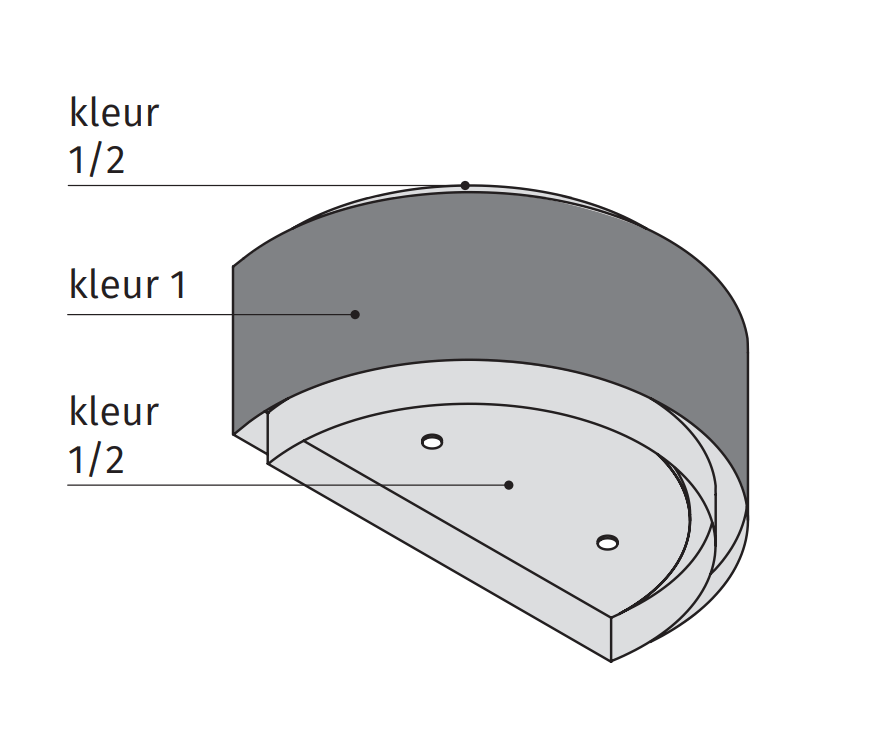

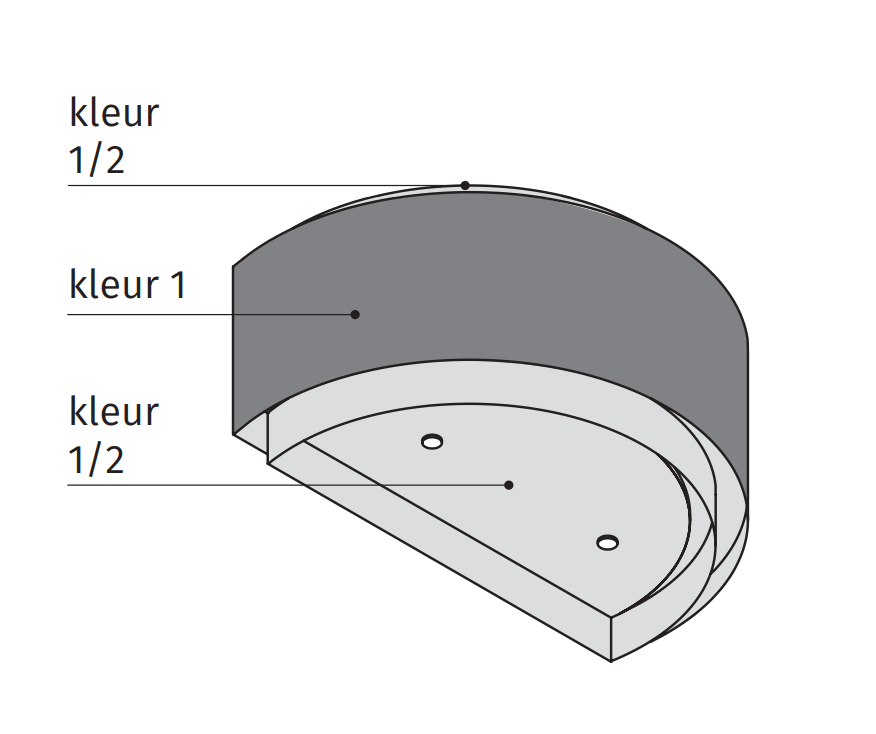

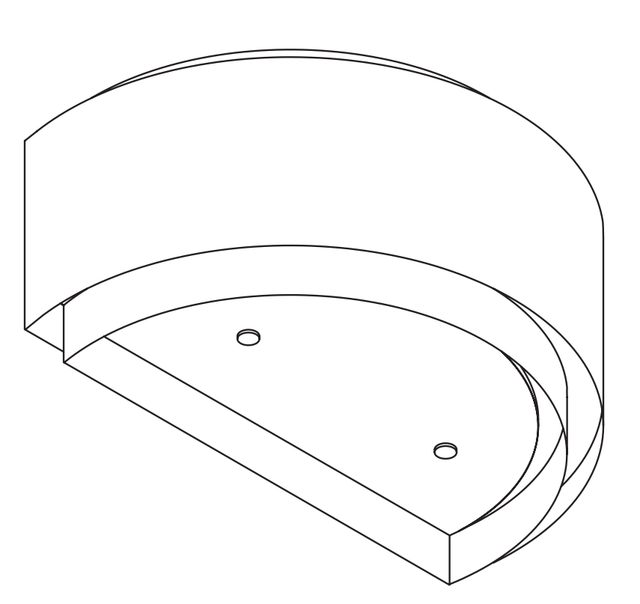

Wave 1640.304 GLOBAL wall-mounted extractor hood 90 cm - suitable for leather upholstery - RAL 9017 matt (black) - internal recirculation motor - LED

Heb je een vraag hierover?

Version Wave 1640.304 GLOBAL recirculation extractor hood

fixed internal motor 850 m³/h - 58 dBA - max. 250 W

recirculation based on carbon filter 99202.27 or plasma filter 99202.02

remote control - 3 settings + intensive + timer

grease filter 1 x aluminium filter + edge extraction

lighting 2 x 4.5 W dimmable LED - 2700 Kelvin

net weight 32 kg

Additional information Wave 1640.304 GLOBAL extractor hood for recirculation

extractor hood is equipped with an internal socket for a plasma filter

space between bottom of extractor hood and worktop minimum 650 mm - maximum 900 mm

model is available in a drain version - ask about the possibilities

-

MotorYes

Alphenberg leather in collaboration with Wave

Leather exudes strength, but at the same time has a chic and timeless look, which also looks modern. It fits effortlessly into any interior. Due to its special qualities and properties, leather is suitable for applications on furniture, doors, fireplaces and unexpected design elements, such as in the kitchen. At Alphenberg, everything revolves around the passion for leather, and we are happy to share that passion with you.

Wave works with different materials for our design elements on a daily basis, including leather. In collaboration with Alphenberg, we have developed a unique extraction unit with leather upholstery. A beautiful example of craftsmanship that offers the perfect balance between design and technology, applicable to various models. Alphenberg is the specialist in leather and high-end interior applications, and we are happy to make use of their expertise.

Do you have questions about Wave products? The WKP team is here to help.

You are most welcome in one of our showrooms to discuss with an advisor which extractor hood fits best in your kitchen interior. If you make an appointment in advance, you can be sure that there is plenty of time for you.

Kantoor WKP

Meidoornlaan 52d

4902 SC Oosterhout

T 0162 – 47 26 26

Showroom DTC

Nijverheidscentrum 2

2761 JP Zevenhuizen

* Visits by appointment only

Of course, questions can also be answered by phone. The team can be reached on workdays at 0162-472626. Or visit the Wave support page